Infrared Patches: Uncovering the Hidden Dangers of Covert IR Patches

Is Your IR Patch Compromising the Saftey of You and Your Team?

Infrared (IR) patches serve as a protective measure against friendly fire incidents in military and law enforcement operations. However, not all IR patches offer the same level of protection, and some may even endanger you and your team. To guarantee the quality and safety of your IR patch for identification friend or foe (IFF) purposes, it is vital to address key questions.

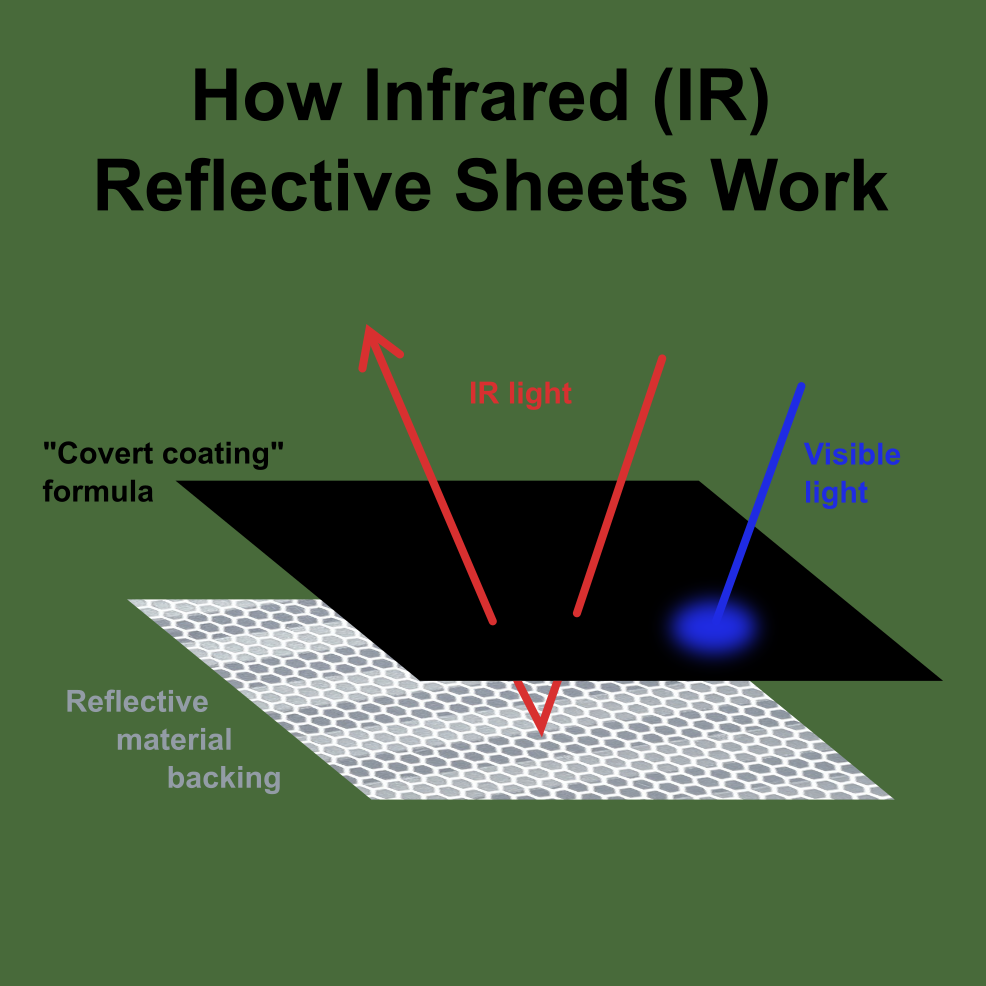

Comprehending the Functioning of IR Patches

IR patches are engineered to reflect only IR light from a reflective material backing, like a bicycle reflector. The light source can be an IR illuminator, white light from a flashlight, a vehicle, or the moon/stars. A unique formula or "covert coating" forms a black layer over the reflective material backing, preventing visible light from passing through, but allowing IR light to penetrate and reflect off the backing. This enables individuals with IR viewing devices (e.g., night vision devices) to see the reflected infrared light, recognise the patch text, and identify you as friendly or by your callsign/name.

Does Your Patch Reflect Visible Light?

A genuine IR patch should only reflect IR light, without reflecting any visible light. Be cautious of fake IR as some manufacturers argue that there are two types of IR reflective patches:

- Covert, which is the true IR for the battlefield

- “Non-covert”, which some people claim is true IR but reflects visible light as well.

The problem arises when an IFF patch marketed as covert actually reflects white light, potentially disclosing your position and leaving you exposed on the battlefield. A covert IR patch must have a high-quality "covert coating" that prevents white light reflection. Always test your IR patches against white light reflection to ensure your safety.

Can Your Patch Be Seen from a Distance?

A limited glow radius on your IR patch could also be hazardous. If the patch's glow is faint and not visible from a distance, you might not be recognisable to friendly forces. The quality of the reflective backing and "covert coating" is crucial in this regard. Both components must be of high quality to maximise reflection and allow the maximum amount of IR light to pass through. Always verify the glow radius on your IR patch using a night vision device before deployment or use. A high-quality IR patch glow should still be visible up to 700m away.

Is Your Patch Resistant to Water and Debris?

Water and debris infiltration can compromise IR patches, causing them to disintegrate and fail. This problem often results from manufacturers cutting costs on raw materials, taking shortcuts in the production process, or neglecting thorough testing before distribution. A disintegrating IR patch is useless for IFF protection and puts you in danger. IR patches require high-quality materials, including reflective backing, black covert coating, nylon overlay, adhesive, and Velcro backing. A frequently overlooked manufacturing technique is the rolled edges of the patch, which not only prevent light from "bleeding" out of the edges but also enhance the patch's durability and water resistance.

Our Patches

The supplier we selected for the best-performing IR sheets is a US company that produces a lot of patches for the US military and has invested substantial time in perfecting its covert coating formula. They use 3M's reflective backing, the industry's top supplier, and apply their high-quality covert coating that absorbs or reflects all visible light while allowing maximum IR light reflection. Combined with our superior adhesive (also from 3M), nylon, and manufacturing techniques like rolled edges and triple-stitched borders, we believe our patches are among the best available because we use the finest materials possible. We never cut corners when it comes to potential life-or-death situations.

It is crucial to thoroughly evaluate the quality and effectiveness of IR patches in providing IFF protection. By addressing these questions, you can be sure of the safety and reliability of your IR patch.

- Does Your Patch Reflect Visible Light?

- Can Your Patch Be Seen from a Distance?

- Is Your Patch Resistant to Water and Debris?

Taking these precautions will help keep you and your team secure in critical situations.

Remember, the safety of you and your team depends on the quality of your equipment. Don't compromise on the quality of your IR patches, as they play a crucial role in identification and avoiding friendly fire incidents. Invest in high-quality patches made by reliable suppliers and ensure they meet the necessary standards. By doing so, you are prioritising the well-being of your team and contributing to the overall success of your missions.

Testing response

Leave a comment